Heat-Treatment

Heat-Treatment is one primary markets Neftec supports and suppliers with their trusted Carbon/Carbon composites.

An area that was once dominated by High temp alloys and Graphite is now being replaced by C/C composites (CFC) due to end users understanding the advantages C/C has over these existing materials. Those advantages being lightweight, high strength, durability and excellent thermal conductivity.

We have extensive knowledge working with small, medium and large scale metallurgical industries and their heat-treatment technologies. This includes; annealing solution heat treatment, brazing, sintering, gas and oil hardening.

C/C Composites supporting Heat-Treatment

C/C (Carbon/Carbon) composites are widely used in a broad range of heat-treatment applications due to their exceptional thermal stability, mechanical strength, and resistance to thermal shock. From furnace fittings to fixtures, these advanced materials are ideal for high-temperature environments where traditional materials like metals or graphite may fail. Our C/C composites are trusted by leading industries, including Aerospace, Automotive, Semiconductor, and Energy, for their ability to deliver consistent performance under extreme conditions.

C/C Composites supporting Heat-Treatment

- Furnace Trays and Baskets

Function: Used to hold and transport components during heat treatment.

Why C/C Composites? Their high strength and thermal stability ensure they can withstand repeated heating and cooling cycles without warping or degrading. - Heating Elements

Function: Provide uniform heat distribution within the furnace.

Why C/C Composites? Their excellent thermal conductivity and resistance to oxidation make them ideal for high-temperature heating applications. - Heat Shields and Insulation Panels

Function: Protect furnace walls and control thermal gradients.

Why C/C Composites? Their low thermal conductivity and high-temperature resistance ensure efficient heat retention and energy savings. - Fixtures and Supports

Function: Hold components in place during heat treatment.

Why C/C Composites? Their lightweight and high strength reduce load on the furnace while maintaining structural integrity. - Quenching Plates and Fixtures

Function: Used to rapidly cool components after heat treatment.

Why C/C Composites? Their thermal shock resistance ensures durability during rapid temperature changes. - Gas Nozzles and Ducts

Function: Direct inert or reactive gases into the furnace for controlled atmospheres.

Why C/C Composites? Their chemical inertness prevents contamination and ensures consistent gas flow.

- Thermocouple Protection Tubes

Function: Protect temperature sensors in high-temperature environments.

Why C/C Composites? Their thermal stability and resistance to chemical reactions ensure accurate temperature monitoring. - Sintering Plates and Boats

Function: Used in powder metallurgy and ceramic sintering processes.

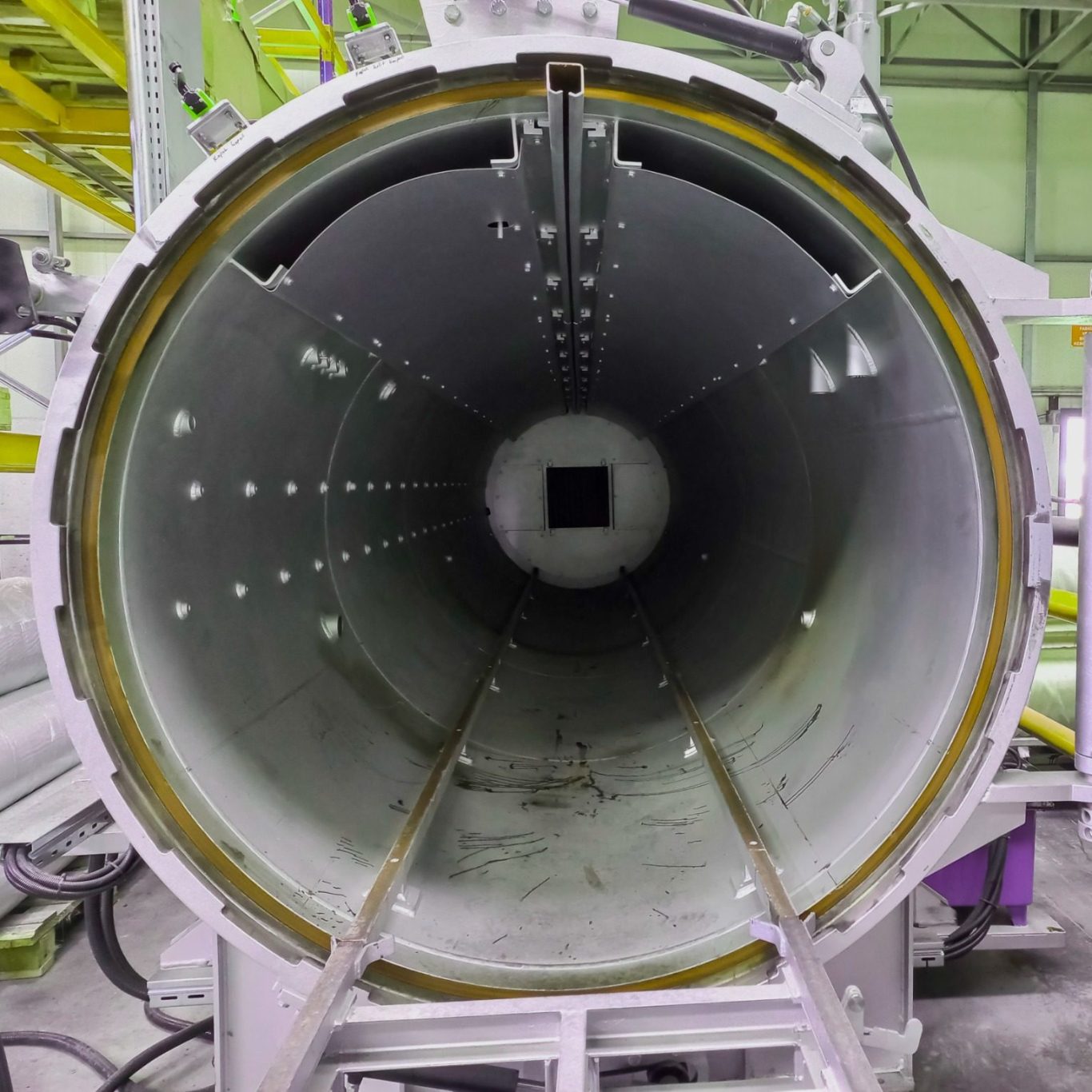

Why C/C Composites? Their ability to withstand extreme temperatures and chemical environments makes them ideal for sintering applications. - Vacuum Furnace Components

Function: Used in vacuum or inert atmosphere heat-treatment processes.

Why C/C Composites? Their low outgassing properties and high purity ensure minimal contamination in vacuum environments. - Annealing Trays and Racks

Function: Hold components during annealing processes to relieve stress and improve material properties.

Why C/C Composites? Their thermal stability and resistance to deformation ensure consistent results. - Brazing Fixtures

Function: Hold components in place during high-temperature brazing processes.

Why C/C Composites? Their ability to withstand high temperatures without reacting with brazing materials ensures clean, precise joints. - Hot Press Plates

Function: Used in hot pressing processes to shape and densify materials.

Why C/C Composites? Their high strength and thermal conductivity ensure uniform pressure and temperature distribution. - Rollers and Guides

Function: Used in continuous heat-treatment furnaces to transport components.

Why C/C Composites? Their wear resistance and thermal stability ensure smooth operation in high-temperature environments.

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.